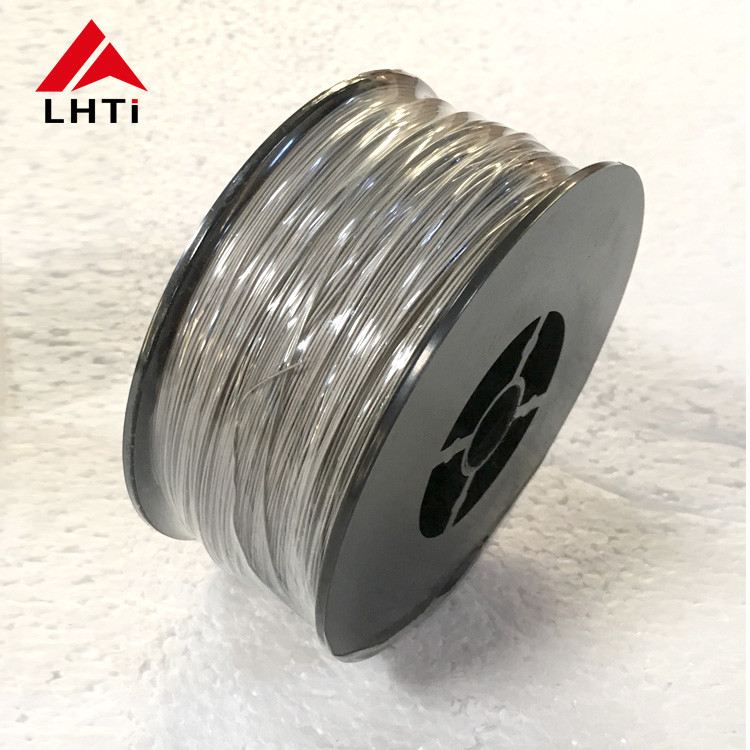

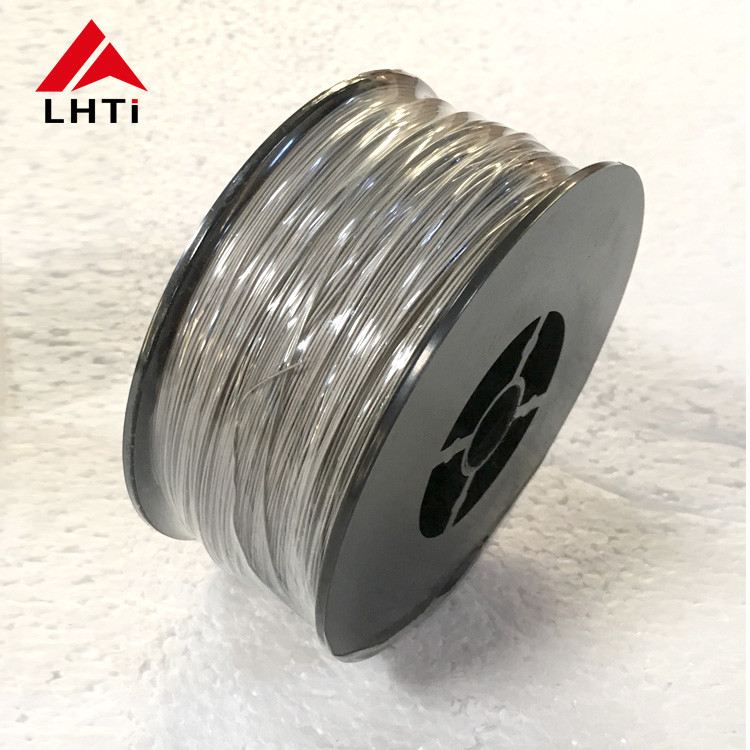

Know the Types of Change Core Stainless Steel Welding Cord

Famously known as tubular electrode welding, the change core welding procedure has actually advanced from the MIG stainless-steel welding approach. It enhances steel transfer, arc activity, boosts weld metal properties and also weld surface. If you want to boost the productivity of a welding steel through higher deposition rates, you can take advantage of flux-cored cords. Flux-cored cords are favored because of their weld top qualities and high performance as well as suitability to a large range of industries like manufacturing, basic manufacture be it offshore, building and construction and shipbuilding.

The flux-cored welding cords are additionally called electrodes. They are hollow tubes in a structure that are loaded with mixtures of metal powders, deoxidizers, fluxing representatives, and ferroalloys. Flux-cored cords are extremely comparable to strong cool drawn cables but with a small distinction that is the closure seam. Flux-cored wires come with unique attributes, advantages, needs, and limitations. Recognizing the features of every private type can aid you understand which of them the ideal one for you is..

Uses, Types, and Features of flux-cored wires.

You can find flux-cored cables typical in either gas protected or shelf protected varieties. Some of the selections of flux-cored cords are made to be suitable for all setting welding, specifically the gas-shielded ones. They produce a slag when used and that aids you to secure the weld steel in its fluid state throughout air conditioning. Nevertheless, see to it to remove this slag gradually as soon as welding is done..

Flux-cored wires are offered for welding various base products like reduced alloy steel, moderate steel, stainless steel, as well as Nickle alloys. If you are welding stainless steel, you can make use of flux-cored cords in tensile toughness of 70 KSI. If the steel has moderate strength or higher welding toughness, you can opt for flux-cored wires with a tensile stamina of 80 KSI or even more..

Self-shielded change cored cables.

When you utilize self-shielded flux-cored cables, you would certainly see their securing gas at the time when the arc starts. Therefore they entirely wipe out the requirement for an added gas cylinder. This makes self-shielded flux wires to be ideal for remote or portable applications. While using them for welding, you would certainly likewise see that they generate a little greater quantities of spatter and also smoke than the gas protected change cored cables. Yet various self-shielded wires provide effect durability, even if made use of at low temperature levels.

If you try to find self-shielded change cords out there today, you would certainly be astonished to see so many variants. Each has special designs to cater to distinct welding demands and placements. If the cable has a high deposition rate, it appropriates to be utilized for thick metal bodies only. This is additionally the case with gas-shielded flux-cored stainless-steel cords. An additional major difference between the two is that self-shielded flux-cored wires don't create slag throughout the procedure of welding. Therefore, these flux-cored cables can not be utilized for vertical welding..

Gas secured change cored cords.

These flux-cored wires call for an additional shielding gas. weldermetals.com can be either a combination of argon and also carbon dioxide or 100% Carbon dioxide. They are taken into consideration to have a higher operator allure, suggesting that they are less complicated to be made use of. Additionally, these cables are extra preferable if you intend to produce a visually pleasing weld. Generally, you would certainly discover these kinds of flux-cored cables to be utilized in store settings. When used, these kinds of wires might utilize an obstacle. It can either be a camping tent or various other ways to secure the welding swimming pool to ensure that the protecting gas doesn't get blown away..

Usually, the diameters of these kinds of flux-cored cords range from 0.035 to 7/67 inches. You can use gas-shielded cables rather than strong cords to enhance efficiency due to their higher deposition rates..

These sort of cables are more economical than the previous ones. The self-shielded cables consist of extra core materials and also alloy aspects but don't require welders to schedule exterior securing gas. However, they are much less reliable when compared to gas-shielded cords. So take into consideration these aspects while you select which of the flux-cored wires you need to choose.

The flux-cored welding cords are additionally called electrodes. They are hollow tubes in a structure that are loaded with mixtures of metal powders, deoxidizers, fluxing representatives, and ferroalloys. Flux-cored cords are extremely comparable to strong cool drawn cables but with a small distinction that is the closure seam. Flux-cored wires come with unique attributes, advantages, needs, and limitations. Recognizing the features of every private type can aid you understand which of them the ideal one for you is..

Uses, Types, and Features of flux-cored wires.

You can find flux-cored cables typical in either gas protected or shelf protected varieties. Some of the selections of flux-cored cords are made to be suitable for all setting welding, specifically the gas-shielded ones. They produce a slag when used and that aids you to secure the weld steel in its fluid state throughout air conditioning. Nevertheless, see to it to remove this slag gradually as soon as welding is done..

Flux-cored wires are offered for welding various base products like reduced alloy steel, moderate steel, stainless steel, as well as Nickle alloys. If you are welding stainless steel, you can make use of flux-cored cords in tensile toughness of 70 KSI. If the steel has moderate strength or higher welding toughness, you can opt for flux-cored wires with a tensile stamina of 80 KSI or even more..

Self-shielded change cored cables.

When you utilize self-shielded flux-cored cables, you would certainly see their securing gas at the time when the arc starts. Therefore they entirely wipe out the requirement for an added gas cylinder. This makes self-shielded flux wires to be ideal for remote or portable applications. While using them for welding, you would certainly likewise see that they generate a little greater quantities of spatter and also smoke than the gas protected change cored cables. Yet various self-shielded wires provide effect durability, even if made use of at low temperature levels.

If you try to find self-shielded change cords out there today, you would certainly be astonished to see so many variants. Each has special designs to cater to distinct welding demands and placements. If the cable has a high deposition rate, it appropriates to be utilized for thick metal bodies only. This is additionally the case with gas-shielded flux-cored stainless-steel cords. An additional major difference between the two is that self-shielded flux-cored wires don't create slag throughout the procedure of welding. Therefore, these flux-cored cables can not be utilized for vertical welding..

Gas secured change cored cords.

These flux-cored wires call for an additional shielding gas. weldermetals.com can be either a combination of argon and also carbon dioxide or 100% Carbon dioxide. They are taken into consideration to have a higher operator allure, suggesting that they are less complicated to be made use of. Additionally, these cables are extra preferable if you intend to produce a visually pleasing weld. Generally, you would certainly discover these kinds of flux-cored cables to be utilized in store settings. When used, these kinds of wires might utilize an obstacle. It can either be a camping tent or various other ways to secure the welding swimming pool to ensure that the protecting gas doesn't get blown away..

Usually, the diameters of these kinds of flux-cored cords range from 0.035 to 7/67 inches. You can use gas-shielded cables rather than strong cords to enhance efficiency due to their higher deposition rates..

These sort of cables are more economical than the previous ones. The self-shielded cables consist of extra core materials and also alloy aspects but don't require welders to schedule exterior securing gas. However, they are much less reliable when compared to gas-shielded cords. So take into consideration these aspects while you select which of the flux-cored wires you need to choose.

Created at 2021-06-27 13:35

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE